Some of the most popular articles on the Six Sigma Study Guide website have been Jeremy Garrett’s application of quality techniques to the teaching profession. In his latest article Jeremy provides great real-life examples how performing root cause analysis can change lives.

Be sure to check out Jeremy’s other articles:

- How Lean Six Sigma Saved my Teaching Career

- How Control Charts Made Me a Better Teacher

- How Advanced Control Charts Can Save Our Schools

On to Jeremy.

In my first article I explained how Lean Six Sigma had shown me that I can view and treat almost any situation as a modifiable process – although it had been hard for me to see, I actually was in control of situations that seemed fated or inevitable. That realization made me a happier, better person and a much better teacher. In order for such realizations to have power we must look for the true causes of the problems we encounter; thus the main topic of this article is on the ways in which “root cause analysis” can transform our lives and our schools.

In society we arrest and jail our criminals, as we must, but then we frequently find that they end up in jail again. Yes the criminal was the “cause” of the problem, but often the criminal behavior was itself the result of something that came before. For example, if someone is addicted to drugs, they might steal in order to pay for the drugs; sending them to jail doesn’t solve the underlying drug addiction problem, so that person robs again. When we fail to look deep enough we find ourselves struggling and building up frustration.

Another example of the need for root cause analysis can be found in firefighting. When a person first tries to put out a fire (perhaps in the Boy or Girl Scouts) he or she will often aim water at the flames. Spraying water at the flames makes a lot of steam and appears to produce a result, but it will never put out the fire. Moving the water spray a little lower onto the upper sticks produces a better result, but moving the spray to the very bottom where the burning coals are located puts out the fire almost immediately.

Lean Six Sigma and other quality assurance systems provide formal training on root cause analysis. But even without formal training this type of reasoning can radically transform the lives of each of us and the lives of those around us including students, children, employees, and more.

During my first teaching job I witnessed a coworker rescue one of my students from a terrible life by using “root cause analysis.” The student in this story was in my sixth period class, and the hero of this true story was her first period teacher – an English teacher with no training in project management, equipment failure analysis, or any form of quality assurance. Even so, it was the English teacher not me that is the hero of this story.

Although I cannot name the student, I can tell you about her. She was 15 years old, well behaved, and was clearly interested in doing well in school. Unfortunately though she almost never completed her homework and she clearly didn’t study before her tests. As a result, she passed her classes, but usually just barely. One day late in the spring she came to school with a large second degree burn covering much of her right forearm. (It was bandaged, so there was no immediate concern of infection.) When she got to class her classmates and her first period teacher (the English teacher I described) asked her how she burned her arm. She explained that she was cooking macaroni and that when she lifted the lid off of the boiling water the steam rose up and scalded her arm. Now many people, including teachers, would have simply thought that it was unfortunate situation and moved on. Her English teacher however asked her “why” over and over until she discovered the root cause of the burn – which turned out to be the root cause of the low grades as well. The root cause turned out to be that she and her younger sister were nearly always left alone without supervision or prepared food. Upon hearing this, the teacher contacted the local social services. The two girls were temporarily placed in foster care, and then two weeks later they moved in with their grandmother. Afterward, the one that was in my class was happier, healthier, and her grades rapidly improved. In the years since this true event I have worked hard to be alert to the subtle signs that my students give and to try to live up to the model set by that English teacher.

In spite of her lack of quality assurance training, that English teacher rescued those teenage girls by using a form of the quality assurance tool known as “The Five Why’s.” This technique begins by asking “why?” It then requires us to ask, “But why did that happen,” until we get to an object or a process that we can correct. The “five” part of the name comes from the observation that five iterations of this question is typically needed. The technique and this name were made famous in manufacturing, management, and quality assurance by Sakichi Toyoda himself. Taiichi Ohno built upon this when he created the famous and influential Toyota Production System.

The power or even “magic” of this technique is that it quickly and painlessly pushes us past the common, human temptation to lay blame on something or someone and then walk away. The temptation to blame someone or something and then quit is tremendously powerful – it can feel very good in the short-term to say, “He [or it] was at fault, not me!” But assigning blame doesn’t solve any problems. Continuing to ask “why” can identify the true and correctable cause of a problem. In the case of the student, if the English teacher had quit one question too soon, she might have concluded that the student was simply a bad cook and the student would not have received help from social services (and her grandmother) and she and her sister would remained neglected and abused.

This same “magic” can be used in nearly any environment and nearly any situation. In that story one person literally asked a second one “why” 4 or 5 or 6 times until the real cause was discovered. In other situations a person might sit and ask themselves that question. Frequently it is used with a small group of people who are familiar with a particular problem, and in these situations a special facilitator is sometimes called into lead the discussion. In all of these situations, the answer to each question must be examined to see if a correctable object or process has been found, if not then “why” must be asked again. The weakness of using this process all by itself is that the person using it can very easily focus in on only the first cause that he or she becomes aware of. Fortunately there are several very easy to use tools that can quickly and easily help us find all (or at least most) of the causes of a problem.

The first tool that I want to talk about is one that is used in education by students and teachers on a frequent basis throughout our country – the “bubble map.” Bubble maps can be created to analyze almost anything, whether it causes of a problem or organizing descriptive data. To begin, simply write the name of the topic in the center of a page and draw a circle or “bubble” around it, in our case we would write the name (or a short description) of a problem in that centralized “bubble.” The next step is to think of all “big” important pieces of information first – in our case that would be major contributing factors to the problem. Each major item gets its own circle connected back to the central one. Before recording a new item, one must think about whether it is directly related to the central item or if it is instead related to one of the other circles that have already been drawn. Once all of the initial ideas have been recorded, the next step is to work around the “map” thinking of potential causes for each existing “cause.” The power or “magic” of this technique comes from that the natural human desire for a balanced looking image. If we initially find a lot of sub-causes for one “bubble” and not another, our subconscious will nearly force us to go back and look for more sub-causes in order to make the map look more balanced. The result of which is a natural, yet fun and automatic push for a thorough investigation.

Here is a “bubble map” (also called a “mind map”) that I created. It shows an exploration of possible causes for a student’s low grades.

As I’m sure readers will point out, even at this size, not all possible causes have been listed. My favorite way to make these is with a very large dry erase board and a set of colored dry erase markers. Creating them by hand allows for a certain spontaneity that can disappear when using a software based method. Hand drawn images can always be photographed or duplicated later. MS Word and most word processors come with circle and line drawing tools and textbox tools, making it possible to draw such diagrams, but those techniques are generally time consuming and generally only suited to duplicating a pre-planned map. There are many nice computer programs that can help with the creation of these maps – I created the one above using free, browser-based software at: https://www.text2mindmap.com/.

This type of graphic organizer has several advantages including free thought flow and the build-in encouragement to look for additional sub-causes. This most closely resembles the “affinity diagram” that is a standard quality assurance tool. The only real difference is when ideas are categorized. With “bubble maps” users are typically encouraged to immediately place an idea alongside related ideas. Generally “affinity diagrams” are created by first listing all possible ideas, then looking for groups, and then drawing a diagram showing how things are grouped. “Bubble maps” (or “mind maps”) always use lines to directly show how levels related to each other, but the lines are considered as optional according to much of the literature on “affinity diagrams.”

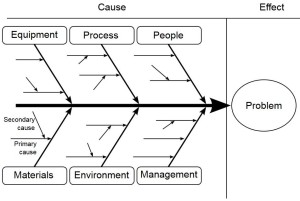

Used alone both of these have two substantial limitations. The first is that they don’t contain a built-in mechanism to ensure that all of the broad, yet critical categories of problems are included in the initial step. Mr. Ishikawa’s “fishbone diagram” however solves this problem by providing the initial branches; his diagram gets its name due to the arrangement of its parts in a shape that looks like fish bones rather than bubbles.

One of the most common ways to start is with the following six main categories (aka 5 Ms and one p): methods, machines (equipment), people (manpower), materials, measurement, and environment. That set was designed primarily for uses with problems that arise in manufacturing; so it is frequently modified when used in other industries. Once the initial structure is created, it is finished using the same steps as those used for the “bubble map.” (In some situations, the contents of the fishbone diagram are copied from a previously completed affinity diagram.)

Here is an image of basic fishbone diagram (copied from the Wikipedia Commons – an open source library).

The one other major weakness that still remains with all of these diagrams is that none of them can indicate which cause is the “most important” one. In order to address this problem, a Pareto chart is some times used to distinguish the “critical few” problems (or problem causes) from the “trivial many.” It is my intention to make this topic and its applications the focus of my next article.

As I described at the beginning, root cause analysis and the tools typically used are very powerful and can be used in any industry – and even in our own lives. What is more important than the tools themselves is the positive attitude and general empowerment that accompanies these tools.

I began by sharing a success story that motivated me and that still inspires me eight years later. In that story a teacher believed that she could make a difference, looked for the root cause of a problem, and in so doing dramatically improved the lives of two teenage girls. The main tool that she used was a variation of the “5 Why’s” made famous by Taiichi Ohno’s efforts to eliminate problems in manufacturing. That same positive, proactive approach used by the English teacher in that story can improve situations in any environment – from manufacturing to the classroom to everyday life. Even without neglect or abuse the people around us and under us (our employees, students, or children) frequently feel helpless and feel that their current bad situation is inevitable. Fortunately though many of these problems can be reduced by simply complimenting and encouraging those in our lives. Uplifting others can help them come to the same life changing realization that I had – that we really can change things around us if we work hard and look for the true causes of the problems we face. When uplifting others is not enough by itself, it still provides a comfortable environment in which people can talk and discuss deeper problems.

If you have stories in which a root cause analysis tool has helped you or someone you know, please tell us about it. Perhaps you’ve mapped out possible causes of problems in order to diagnose and repair a car or out of control budget? Although there are books with stories of these techniques being used in manufacturing, your own, real life stories would still be helpful. An exchange of ideas and stories on this general topic would enrich and empower us all.